TRUMPF's New High-Volume Laser Blanking System Saves 1,700 Metric Tons of Steel per Year

TRUMPF's TruLaser 8000 Coil Edition, a new laser blanking solution, is launching in the North American market.

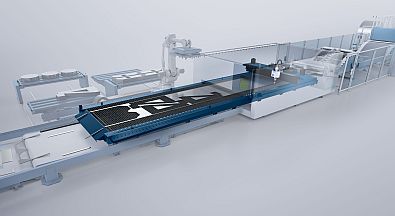

The TruLaser 8000 Coil Edition can process up to 25 metric tons of coiled sheet metal from start to finish without any human intervention. It is an attractive option for companies interested in flexible, high-volume solutions for sheet metal fabrication, including automotive suppliers and automakers, electrical cabinet manufacturers, elevator producers, and HVAC manufacturers.

TRUMPF's TruLaser 8000 Coil Edition processes coiled sheet metal and can be operated completely automatically. (Source: TRUMPF)

"The TruLaser 8000 Coil Edition is another solution from TRUMPF that helps North American customers to join the drive toward greater sustainability in manufacturing while simultaneously boosting efficiency," says TRUMPF Inc. Head of TruLaser 2D Salay Quaranta. "Compared to conventional laser cutting machines, this setup allows companies with high volume manufacturing to save up to 1,700 metric tons of steel a year, which can equate to saving approximately 4,000 metric tons of CO2 and reducing material costs."

Impressive Flexibility Extends to Volume Production

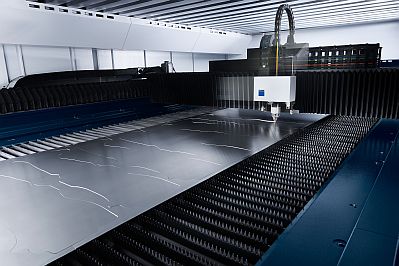

TRUMPF's new laser blanking system helps companies enjoy the benefits of laser processing even in high-volume production environments.

VIDEO: TruLaser 8000 Coil Edition -- Highly productive laser welding from coil

"Volume manufacturers often use die presses for blanking operations, but that means they need to adjust or even replace the tool whenever they make the slightest modification to their components, ultimately costing time and money," adds Quaranta. "Many industries are seeing significant reductions in the scale of individual production runs, which makes modifications even more costly and time intensive. The laser allows users to carry out these modifications without requiring a new tool, so it's much easier, faster, cheaper and more flexible."

At the heart of this new system designed for laser processing in high-volume production environments is a proven TruLaser cutting machine. (Source: TRUMPF)

The TruLaser 8000 Coil Edition has already been successfully implemented by customers in Europe.

In one example, TRUMPF's laser blanking system is used to produce high-strength aluminum structural components for vehicle-body manufacturing. Early adopters of the technology have noted production benefits thanks to the laser blanking system's high flexibility and quality. They also highlight that the system requires fewer tools than conventional blanking presses.

Material Savings for Sustainable Production

Coil production enables users to achieve more efficient nesting of parts.

The system is characterized by its compact design, high speeds, higher process reliability and short coil change times. (Source: TRUMPF)

Conventional sheets are limited by their four outer edges, which often makes it difficult for production workers to make full use of the entire sheet. Unused sections of the sheet either must be discarded as scrap or melted down. A coil solves this problem by allowing users to nest an almost endless number of parts on the sheet, which reduces material consumption by around 15 percent. Compared to conventional blanking presses, the new system also heralds a significant reduction in construction and logistics costs.

The TruLaser 8000 Coil Edition makes production more profitable by eliminating tooling costs, optimizing material use, reducing assembly costs, and boosting flexibility in the production environment.

Automated Laser Cutting Ensures Cycle Times

The production system is fully automated.

One or two robots enable parallel-to-production unloading and precise, repeatable stacking. (Source: TRUMPF)

An innovative system for transporting sheet metal during cutting keeps the material moving quickly through the whole process, with impressive gains in productivity.

The TruLaser 8000 Coil Edition will make its North American debut at FABTECH 2023 but is now available for purchase in the United States, Canada and Mexico.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::